Martin-Baker have been involved in the design, development and testing of escape systems since 1944. Testing has always been an important element of the design and development process and, over the last 78 years, the company has developed a unique set of capabilities to ensure we are at the cutting edge of aircrew safety.

THE WORLDS ONLY MANUFACTURER OF FULLY INTEGRATED ESCAPE SYSTEMS

Design & Manufacture

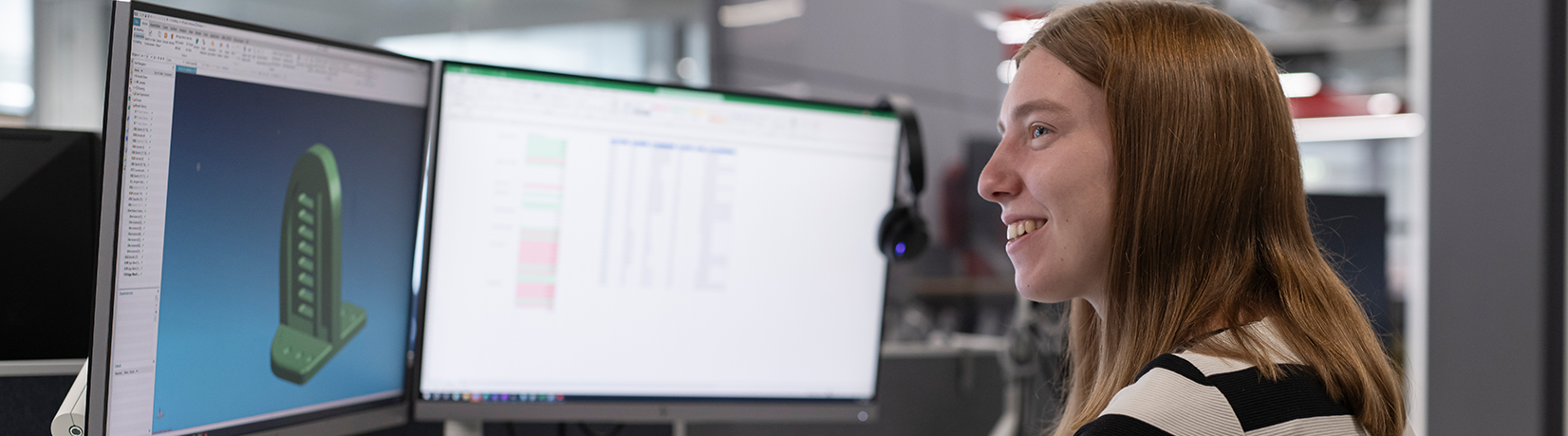

A talented team of Design Engineers from a host of Engineering disciplines start the process of manufacturing an ejection seat. From our apprenticeships to our graduate engineering programmes, we invest in the capabilities of our people to use the latest technology and latest engineering practices.

Using the wealth of knowledge gained in a career of machining, our engineers write Computer Aided Manufacture programs to run on the various machines we have at both Denham and Chalgrove. Our facilities hosts a wide rage of machinery from 5-axis mills to specialist one-of-a-kind honing and broaching machines. In our machine shop, we run 24+ hours a day, 7 days a week to keep up with the demand for our life saving equipment.

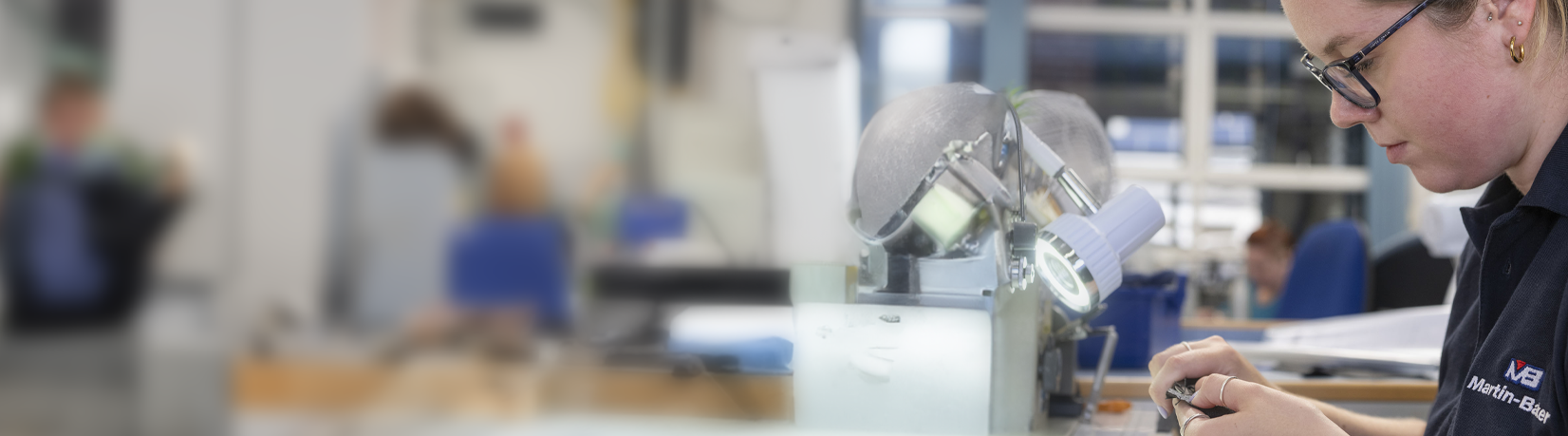

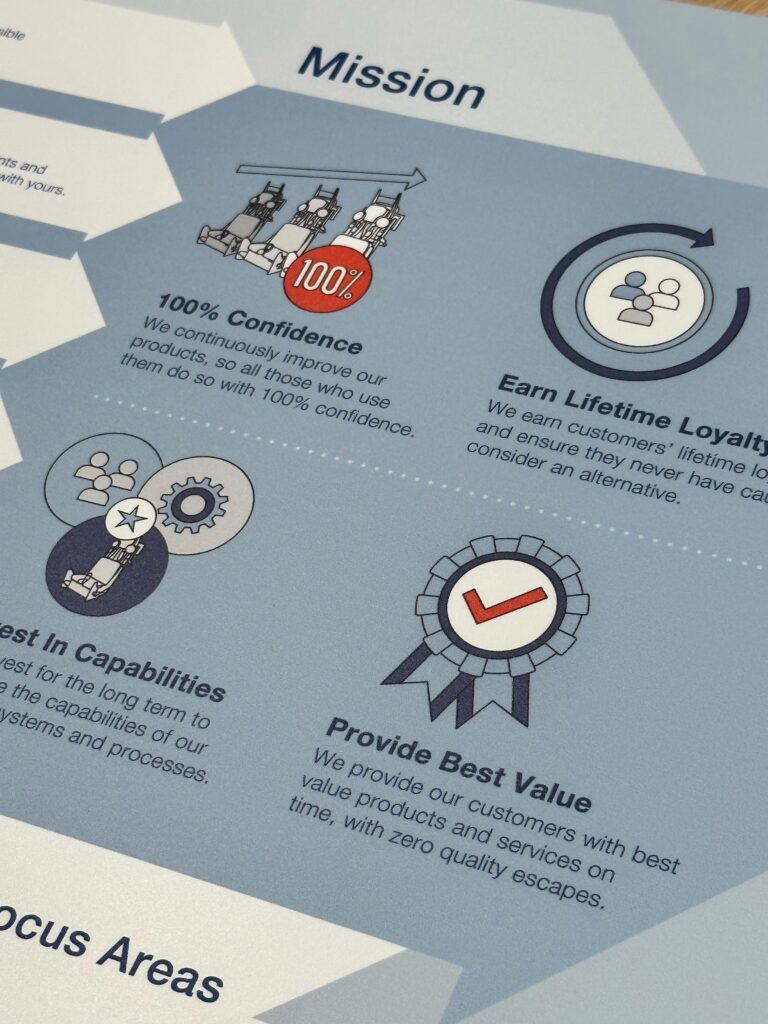

We have a quality culture built into our process at Martin-Baker to give the pilots who use our seat 100% confidence. We invest in the latest inspection technologies like Coordinate Measurement Machines (CMMs) and laser scanners and our Non-Destructive Testing equipment including Dye Penetrant testing and X-ray machines.

Component & Environmental Testing

We test individual components as well as our fully assembled seats to ensure they will last the full-service life of an aircraft. To simulate the conditions our seat might be subject to over its lifetime, we conduct numerous environmental and structural tests.

- Our environmental chamber testing includes high and low temperature, salt fog (and sulphur dioxide), humidity and altitude.

- Our mechanical testing includes vibration, shock, tensile/compressive, static load, abrasion and drop testing.

- Our ballistic testing includes ballistic signal transmission tests, rocket motor firing, cartridge firing, parachute deployment and retraction tests.

- Our functional tests include endurance and inflation tests.

Ejection Seat Performance Testing

Opened in 1971 and built by Martin-Baker employees, our Langford Lodge Test Track has seen over 400 high-speed ejection tests. It features a purpose-built preparation facility and a moveable building to cover the sled prior to a test. The track, situated in Northern Ireland, is 6,000ft (1.8 kilometres) long allowing for speeds up to 625 knots or 320 meters per second.

Chalgrove Airfield, Oxfordshire has been the site of ejection testing since the 1946 and continues to be used for zero/zero ejections, over 800 airborne tests from our 2 specially modified Meteor aircraft, canopy jettison tests, net tests, low-speed truck tests and ejections using our ejection tower.

Our dedicated photographic team capture every detail in high-speed slow-motion video from every angle.

MRO & Training

We pride ourselves on our ability to service and maintain ejection seats across 6 continents. We have a number of partnerships across the world to ensure seats are kept at the highest standard. Our network of field service engineers (FSEs) and instructors train every facet of the seat to ensure pilots are operating safely and that ejection seat maintainers are working to best practices.

The Martin-Baker Training School is based at our Denham HQ where a team of instructors are responsible for training customer personnel in seat maintenance and specialist tasks like parachute and survival kit packing.